In high-risk industries like construction, oil and gas, and manufacturing, dropped objects prevention safety nets are a critical safety measure to protect workers from falling tools, debris, and equipment. According to OSHA, falling objects cause hundreds of injuries and fatalities annually, making proper safety net systems essential for compliance and worker protection.

This guide explores the importance of dropped objects prevention safety nets, their benefits, types, installation best practices, and how to choose the right solution for your worksite.

1. The Risks of Falling Objects in the Workplace

Dropped objects are a leading cause of workplace accidents, particularly in industries where work is performed at heights. Common hazards include:

- Falling tools (hammers, wrenches, power tools)

- Loose equipment (bolts, scaffolding parts)

- Structural debris (concrete fragments, metal scraps)

Consequences of dropped objects:

✔ Worker injuries & fatalities (head trauma, fractures)

✔ Equipment damage & project delays

✔ Regulatory fines & legal liabilities

Proper dropped objects prevention safety nets can significantly reduce these risks.

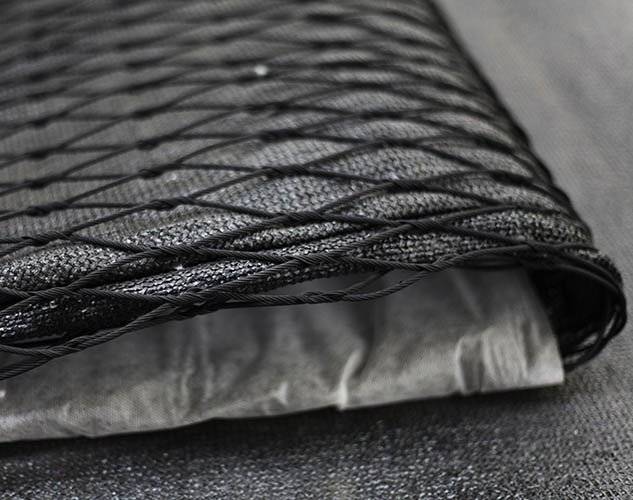

2. What Are Dropped Objects Prevention Safety Nets?

These are high-strength barrier systems designed to catch and contain falling objects before they strike workers below.

Key Features:

✅ Durable materials (polyethylene, nylon, steel mesh)

✅ High load capacity (withstands impact from heavy tools)

✅ UV & weather-resistant (for long-term outdoor use)

✅ Easy installation & maintenance

Common Applications:

- Construction sites (high-rise buildings, bridges)

- Oil rigs & refineries

- Industrial plants & warehouses

- Shipbuilding & aviation maintenance

3. Benefits of Using Dropped Objects Prevention Safety Nets

Investing in high-quality safety nets provides multiple advantages:

A. Enhanced Worker Safety

- Prevents serious injuries by stopping falling objects.

- Reduces workplace accidents, improving morale and productivity.

B. Regulatory Compliance

- Meets OSHA, ANSI, and EU safety standards.

- Helps avoid costly fines and legal issues.

C. Cost Savings

- Reduces downtime from accidents.

- Lowers insurance premiums by improving safety records.

D. Versatility & Durability

- Can be used in multiple work environments.

- Long lifespan with minimal maintenance.

4. Types of Dropped Objects Prevention Safety Nets

Different work environments require different safety net solutions:

A. Debris Nets

- Lightweight, mesh-style nets for catching small falling objects.

- Ideal for construction sites & renovation projects.

B. Tool Arrestor Nets

- Heavy-duty nets designed to stop falling tools & equipment.

- Commonly used in oil & gas, shipyards, and industrial settings.

C. Vertical Safety Nets

- Installed along building edges or scaffolding to catch falling objects.

- Prevents debris from dropping to lower levels.

D. Horizontal Catch Nets

- Positioned below work areas to intercept dropped items.

- Used in high-rise construction & bridge work.

5. How to Choose the Right Safety Net for Your Worksite

Selecting the best dropped objects prevention safety net depends on:

A. Worksite Requirements

✔ Height & drop distance (determines net strength needed)

✔ Type of falling hazards (small debris vs. heavy tools)

✔ Environmental conditions (wind, rain, UV exposure)

B. Material & Strength

- Polyethylene nets (lightweight, corrosion-resistant)

- Steel cable nets (for heavy industrial use)

- Knotless vs. knotted nets (impact absorption differences)

C. Compliance with Safety Standards

Ensure the net meets:

- OSHA 1926.500 (Fall Protection)

- ANSI/ASSE A10.11-2010

- EU EN 1263-1 & EN 1263-2

D. Installation & Maintenance

✔ Professional installation for optimal performance

✔ Regular inspections for wear & tear

✔ Easy-to-clean & repair designs

6. Best Practices for Installing & Maintaining Safety Nets

To maximize effectiveness:

A. Proper Installation

- Follow manufacturer guidelines.

- Ensure secure anchoring to prevent net displacement.

- Use secondary attachment points for added safety.

B. Routine Inspections

- Check for tears, fraying, or weakened areas.

- Test load capacity periodically.

C. Worker Training

- Educate employees on net usage & limitations.

- Conduct safety drills for emergency response.

7. Why Invest in High-Quality Dropped Objects Prevention Safety Nets?

✔ Saves lives by preventing fatal accidents.

✔ Reduces liability & legal risks.

✔ Improves worksite efficiency & morale.

✔ Ensures compliance with global safety regulations.

Dropped objects prevention safety nets are a non-negotiable safety measure for any high-risk worksite. By choosing the right net, ensuring proper installation, and maintaining it regularly, companies can protect workers, avoid costly incidents, and stay compliant with safety laws.

Need expert advice on the best safety nets for your project? Contact us today for a free consultation!

Post time: Apr-02-2025